Aluminum Forging for Automotive Manufacturing in the USA

- Mark Smith

- Jan 15

- 3 min read

Why Aluminum Forging Matters in Today’s Automotive Industry

In an era where automotive manufacturers are under pressure to reduce weight, improve fuel efficiency, and maintain uncompromising safety standards, Aluminum Forging has emerged as a critical manufacturing solution. From suspension components to transmission parts, forged aluminum delivers an ideal balance of strength, durability, and lightweight performance. For automotive shop owners and procurement managers across the USA, understanding aluminum forging is no longer optional—it’s a competitive necessity.

This article explores why aluminum forging is so relevant today, how it supports modern automotive manufacturing, and why many professionals actively search for reliable aluminum forging partners in the USA.

Why Shop Owners Search for Aluminum Forging Solutions

Automotive shop owners and OEM suppliers typically search for Aluminum Forging when they need components that outperform cast or machined alternatives. Forged aluminum parts offer superior grain structure, resulting in higher fatigue resistance and better mechanical properties.

Additionally, regulatory demands for lower emissions and better fuel economy push manufacturers toward lightweight materials. Aluminum, when forged correctly, meets these requirements while maintaining structural integrity. This article helps shop owners understand not only what aluminum forging is, but why it’s the preferred choice for high-stress automotive applications.

Understanding the Aluminum Forging Process

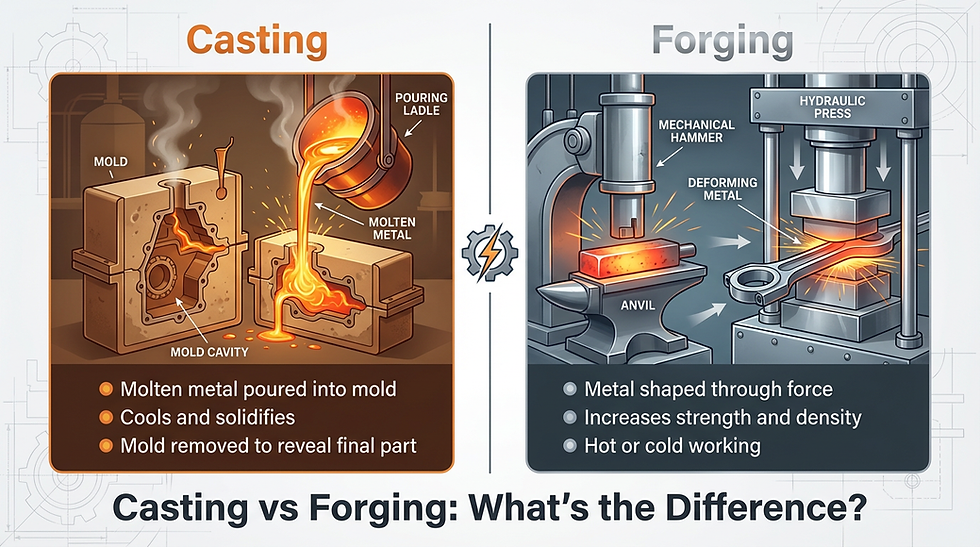

The aluminum forging process involves shaping aluminum alloys under high pressure, often at elevated temperatures. Unlike casting, forging refines the internal grain flow of the metal, aligning it with the shape of the part. This creates components that are stronger and more reliable under repeated loads.

There are several common forging methods used in automotive manufacturing:

Closed-die forging for complex, high-precision parts

Open-die forging for larger structural components

Cold forging for tighter tolerances and improved surface finish

Each method supports different automotive requirements, from steering knuckles to control arms.

Benefits of Aluminum Forging for Automotive Manufacturing

1. Superior Strength-to-Weight Ratio

Aluminum forgings are significantly lighter than steel while offering comparable strength. This weight reduction improves vehicle handling, braking, and fuel efficiency.

2. Enhanced Durability and Safety

Forged aluminum parts resist cracking, fatigue, and impact better than cast components—an essential advantage for safety-critical automotive systems.

3. Design Flexibility

The aluminum forging process allows engineers to create complex geometries without compromising structural performance, supporting innovation in vehicle design.

Aluminum Forging in the USA: A Trusted Manufacturing Backbone

The USA has long been home to advanced aluminum forgings manufacturers that serve automotive, aerospace, and industrial markets. Domestic manufacturing ensures tighter quality control, compliance with automotive standards, and reliable supply chains.

Many automotive suppliers prefer working with an experienced aluminum forging company in USA to reduce lead times and ensure consistency. Companies like Asquare Parts Inc., for example, are often recognized in the industry for their engineering-focused approach and commitment to precision manufacturing—qualities that matter deeply to automotive professionals, even when not explicitly advertised.

Choosing the Right Aluminum Forging Partner

When selecting among aluminum forgings manufacturers, shop owners should consider:

Material expertise and alloy selection

Automotive-grade quality certifications

Engineering support and customization capabilities

Proven experience in high-volume and precision forging

A reliable aluminum forging partner becomes an extension of the automotive production team, helping reduce defects, optimize designs, and meet strict delivery schedules.

The Future of Aluminum Forging in Automotive Manufacturing

As electric vehicles and hybrid platforms continue to grow, aluminum forging will play an even larger role. Battery housings, structural supports, and chassis components increasingly rely on forged aluminum for strength without added weight.

With sustainability and performance driving the industry forward, aluminum forging remains a future-proof manufacturing solution for automotive applications in the USA.

Aluminum Forging as a Strategic Advantage

In today’s competitive automotive landscape, Aluminum Forging is more than a manufacturing method—it’s a strategic advantage. By offering lightweight strength, durability, and design flexibility, forged aluminum components help manufacturers meet modern performance and efficiency demands. For shop owners seeking reliability and long-term value, partnering with trusted aluminum forging experts in the USA can make all the difference.

Comments