Casting vs Forging: What’s the Difference?

- Mark Smith

- Dec 16, 2025

- 3 min read

Choosing the right manufacturing process is a critical decision that directly impacts the quality, cost, and performance of your products. For many industry owners, the debate of Casting vs Forging sits at the heart of this choice. These two fundamental metalworking techniques shape raw metal into finished parts, yet they do so in vastly different ways. Understanding these differences is essential for selecting the method that best aligns with your project's specific needs, ensuring durability, and optimizing your budget. This guide will help you navigate this crucial decision by breaking down each process.

What is Metal Casting?

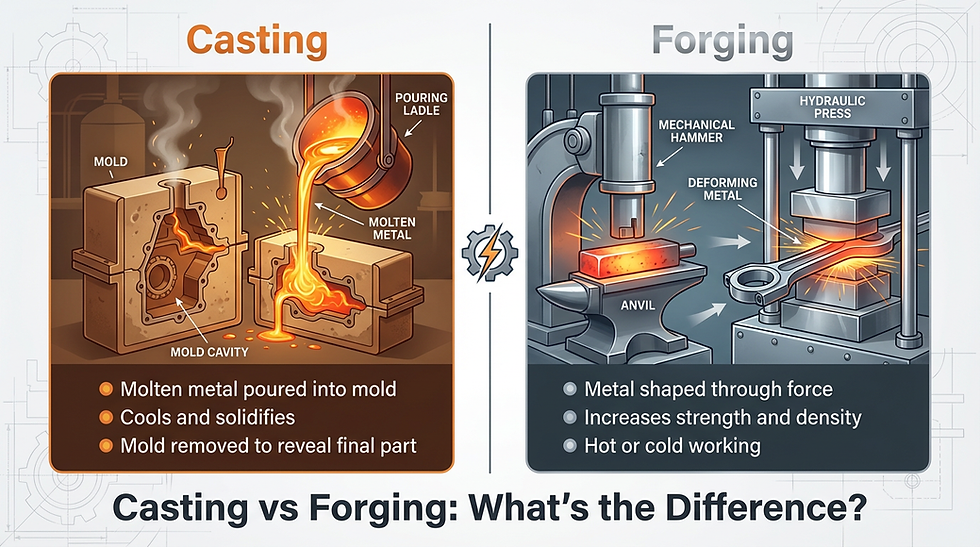

Casting is a manufacturing process where liquid metal is poured into a mold containing a hollow cavity of the desired shape. The molten metal is then allowed to cool and solidify. Once the metal has hardened, the part is ejected or broken out of the mold to complete the process. This method is incredibly versatile, allowing for the creation of large, complex, and intricate designs that would be difficult or impossible to produce with other methods.

Advantages of Casting

Design Complexity: Casting excels at producing complex and intricate geometries, including parts with internal cavities.

Size and Weight: It is one of the few methods capable of producing very large and heavy parts.

Cost-Effectiveness for Volume: For high-volume production runs, casting can be a highly economical choice due to lower material waste and production costs.

Wide Material Selection: A vast range of ferrous and non-ferrous metals can be cast, offering flexibility in material properties.

What is Metal Forging?

Forging is a manufacturing process that involves shaping metal using localized compressive forces. The metal is heated to a malleable temperature and then hammered or pressed into the desired shape. Unlike casting, the metal remains solid throughout the process. This mechanical working of the metal refines its internal grain structure, creating parts known for their exceptional strength and resilience.

Advantages of Forging

Superior Strength and Durability: The forging process aligns the metal's grain flow with the part's shape, resulting in components with high tensile strength and fatigue resistance.

Structural Integrity: Forging produces a tight grain structure that eliminates internal voids, porosity, and other defects common in casting.

Reliability: Forged parts are generally more reliable under high stress, impact, and load conditions, making them ideal for critical applications.

Consistent Quality: The process delivers predictable and uniform part quality from piece to piece.

Key Differences: Casting vs Forging

While both methods shape metal, their core differences lie in the process and the resulting properties of the final product.

Feature | Casting | Forging |

Process | Molten metal poured into a mold | Solid metal shaped by pressure |

Grain Structure | Random, non-directional grain | Aligned, directional grain flow |

Strength | Generally lower tensile strength | High tensile and fatigue strength |

Complexity | Ideal for intricate, complex shapes | Best for simpler, less complex shapes |

Porosity | Can have internal porosity | Dense, non-porous structure |

Cost | More cost-effective for complex designs and high volumes | Can be more expensive due to tooling and process |

Applications of Casting and Forging

Choosing between casting and forging often comes down to the part's end-use.

Casting Applications: Commonly used for engine blocks, pump housings, machine components, pipes, and decorative items where intricate design is more critical than maximum strength.

Forging Applications: Essential for high-performance components like automotive crankshafts, gears, aircraft structural parts, hand tools (like hammers), and industrial hardware where strength and reliability are non-negotiable.

How to Choose Between Casting and Forging

Making the right choice requires evaluating your project's specific requirements. Consider the following questions:

What level of strength is required? If your part will be subjected to high stress or impact, forging is the superior choice.

How complex is the design? For intricate shapes or parts with internal passages, casting offers greater design freedom.

What is your production volume? Casting may offer cost advantages for large production runs, while forging can be competitive for various quantities depending on tooling.

What are the performance demands? For critical applications where failure is not an option, the reliability of a forged part is unmatched.

Leading suppliers, such as Asquare Parts Inc., often provide both casting and forging services because they understand that each method serves a distinct purpose. Consulting with experts can help you analyze these trade-offs effectively.

Ultimately, the Casting vs Forging decision is a balance of performance, design, and cost. By understanding the fundamental strengths and weaknesses of each process, you can make an informed choice that ensures your final product is manufactured for success.

💥💥I found this article on casting vs. forging highly informative and well-structured. It clearly explains the key differences, processes, and uses with practical insights that helped deepen my understanding of both metalworking methods. A valuable read for engineers and manufacturers alike!💥💥🔥

By comparing casting and forging side by side, the article makes decision-making much easier. The explanation shows how each method excels under different conditions and applications.

The article does a great job highlighting how casting and forging serve different purposes in manufacturing. It makes it clear why casting suits intricate designs, while forging is preferred when mechanical strength is critical.

This article clearly explains the difference between casting and forging. It is helpful to understand how casting is better for complex shapes, while forging provides higher strength and durability. The comparison makes it easier to choose the right manufacturing process for different applications.